The SMARTSCAN Aircraft Wheel Inspection System is a turnkey solution for automated and semi-automated testing of aircraft wheels manufactured by Messier-Bugatti, Goodrich, Honeywell, Meggitt and other world-class producers.

Meets the requirement ISO 15548-1

Standards Compliance

Being code-compliant (ISO 15548-1), the System provides a consistent and effective eddy current inspection of the following wheel areas:

- tube well;

- bead seat;

- flange.

Flexible Test Object Parameters

The SMARTSCAN offers flexibility in inspecting wheels with the OD from 7.5 in. (190 mm) to 35 in. (900 mm) and diameters of the centered holes from 1.57 in. (40 mm) to 8 in. (200 mm).

Reliable Modular System

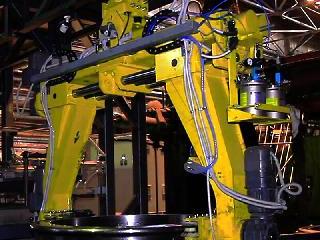

The SMARTSCAN System consists of an eddy current flaw detector (Eddycon D / Eddycon C), a system control station, a table with a roller tray for wheels, mechanisms for lifting, fixing, and rotating the wheel, as well as a mechanism for ECP movement in horizontal and vertical planes.

The SMARTSCAN is a reliable system with high-quality components. Due to its modular design, the maintenance and repair of the system take only a short time.

The System is produced in two versions:

SMARTSCAN

Model SMARTSCAN enables semi-automated inspection of wheels with portable eddy current flaw detectors of different manufacturers.

The SMARTSCAN kit includes Eddycon C flaw detector.

SMARTSCAN-FA

Model SMARTSCAN-FA enables fully automated cycle of inspection with stop on defect mode, storage of inspection results and database creation, as well as printouts of inspection reports, etc.

Eddycon D flaw detector is delivered in the SMARTSCAN-FA kit.

Various versions of the system for aircraft wheel inspection allow wheel shops to select the most suitable kit for their needs to maximize output and automate recording of inspection results.

Reports of wheel inspection may be crucial as a proof of performed wheel inspection and its results.

GET A QUICK QUOTE FROM US TODAY

REQUEST A QUOTEAdvantages of the SMARTSCAN:

- The SMARTSCAN is easy to use and to service.

- The wheel can be inspected flange up and flange down.

- The SMARTSCAN allows testing wheels without a hub with a driven nipple.

- The automatic adaptor reliably centers even heavyweight wheels.

- The SMARTSCAN holds the ECP in place while scanning the wheel profile, even in case of vertical and horizontal wheel shifts during the rotation, which ensures 100% of the inspection area is scanned.

- The operator can comfortably pause the inspection procedure from the control station to verify the indications with manual probes.

GET A QUICK QUOTE FROM US TODAY

REQUEST A QUOTE

Key Features:

- The operator can control the System from the control station at a safe and convenient distance.

- The operator can quickly take the ECP to an inspected wheel and determine the settings (height for wheel lifting, coordinates of the scan start and scan stop); special stop mechanisms prevent the use of excessive force protecting the operator from injuries and the ECP from mechanical damage.

- The SMARTSCAN automatically validates the ECP performance by scanning the reference block before the inspection and on its completion.

- The wheel rotation speed is set up to ensure rapid and reliable testing.

- The inspection helix step is adjustable from .004 to .08 in. (from 0.1 to 2 mm).

- The System lifts and centers aircraft wheels weighing up to 330lbs (150 kg), and spins them at a speed of up to 120 rpm;

- The SMARTSCAN has three operation modes: automatic, stop on defect, and manual.

- The SMARTSCAN also offers a ‘return to defect’ function.

- The System is highly adjustable for wheels of different types and sizes and allows manual tuning of parameters. The setup can be saved for future use.

- The test results are saved to the the Eddycon C memory (SMARTSCAN) or the PC (SMARTSCAN-FA).

- Due to high-quality components and modularity of the System, its repair takes minimum time;

SMARTSCAN System Specifications

| Model | SmartScan | SmartScan-FA |

| System type | Semi-automated | Automated |

| Overall dimensions | 31 x 39 x 49 (in.)* 790 × 990 × 1250 (mm)* | 31 x 39 x 49 (in.)* 790 × 990 × 1250 (mm)* |

| Weight | No more than 882 lbs (400 kg) | No more than 882 lbs (400 kg) |

| Flaw detector | Eddycon C | Eddycon D |

| ECP type | Pencil probe type with a cylindrical head. Frequency — 100 kHz, 200 kHz, 500 kHz, 1.5MHz ECP diameter – 15/64" (6 mm) Other standard ECP types – on request | Pencil probe type with a cylindrical head. Frequency — 100 kHz, 200 kHz, 500 kHz, 1.5MHz ECP diameter – 15/64" (6 mm) Other standard ECP types – on request |

| Max wheel diameter | 35 in. (900 mm) | 35 in. (900 mm) |

| Max System load | 330 lbs (150 kg) | 330 lbs (150 kg) |

| Inspection helix | Adjustable from .004 to .08 in. (from 0.1 to 2 mm) | Adjustable from .004 to .08 in. (from 0.1 to 2 mm) |

| Inspection area | Adaptive tracking of the wheel profile surface | Adaptive tracking of the wheel profile surface |

| ECP vertical movement | 17 in. (430 mm) | 17 in. (430 mm) |

| Rotation speed | 10-120 rpm | 10-120 rpm |

| Inspection speed | up to 33 fps (10 m/s) | up to 75 fps (23 m/s) |

| Alarms | Visual and acoustic | Visual and acoustic |

| Power supply | 110-240 V, 50/60 Hz | 110-240 V, 50/60 Hz |

| Data recording and storage | Yes (Eddycon C memory) | Yes (PC hard drive, database) |

| Manual inspection | Yes (set of ECPs for manual inspection) | Yes (set of ECPs for manual inspection) |

| Remote “Pause” button | Yes | Yes |

| Wheel position | Flange up/Flange down | Flange up/Flange down |

| Automatic reference block calibration | + | + |

| Automatic stop on defect | - | + |

| Turntable | rubber/plastic coated rolls | rubber/plastic coated rolls |

| Control panel | built-in | built-in |

| Operation modes | Block, Manual (with automatic reference block calibration), Automated | Block, Manual (with automatic reference block calibration), Stop on defect, Automated |

| Ports | 3 – USB ports, HDMI or Display port, Ethernet port | 3 – USB ports, HDMI or Display port, Ethernet port |

| PC computer set | Wireless keyboard and mouse, monitor, system unit, special purpose software | Wireless keyboard and mouse, monitor, system unit, special purpose software |

| Adapter set | For wheels without hubs (p/n C20626200 (SAFRAN), p/n 3-1674 (GOODRICH) | For wheels without hubs (p/n C20626200 (SAFRAN), p/n 3-1674 (GOODRICH) |