TOFD Man Ultrasonic Weld Testing System

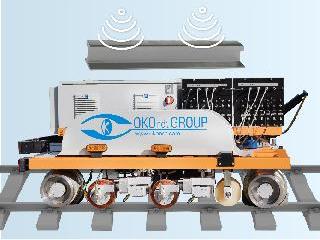

The TOFD MAN Ultrasonic Weld Testing System is an innovative solution in NDT inspection of long welds. Employing wireless technologies, the TOFD MAN overcomes the main weakness of the TOFD technique, a significant degradation of the signal-to-noise ratio, caused by the long signal cable that connects the scanner to the electronic module.

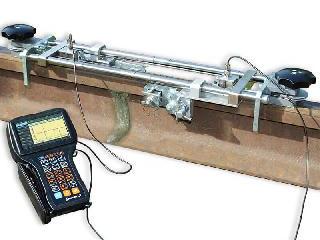

The TOFD MAN is intended for testing welds on cylindrical, spherical, and complex-shaped objects with a radius of surface curvature from 16 ft (5 m) to flatness and a wall thickness from .25 to 2 in (from 6 to 50 mm). For testing objects with a wall thickness from 2 in (50 mm) to 4 in (100 mm), appropriate probe pairs are to be installed, and scanning is to be done in several runs. For the inspection of objects exceeding 4 in (100 mm), the carrier rail of the scanner is to be changed for a longer one, with consequent installation of appropriate probes and several runs of scanning. The number of probe pairs can vary from 1 to 4. The System is capable of testing welds in any direction. The TOFD MAN System is compatible with other scanners, which can be selected depending on the application.

High Mobility and Reliable Results

The TOFD MAN System is placed into the inspector’s utility vest, which allows easy movement, even during rope access inspection. The standard kit comes with an 8-hour rechargeable battery pack, which is easily replaceable with one hand.

Due to the Wi-Fi module, the inspector can operate the device from anywhere within the Wi-Fi range. Alternatively, all the test data saved to the internal memory are transferred to the PC at the end of the inspection, using either wireless or wired connection.

Magnetic wheels and spring-loaded probe carriers with a self-positioning system ensure transducer stability on the object surface, thus providing good acoustic coupling necessary for reliable test results. The scanner is easy to drive and does not fall from the object even when the device is turned upside down.

Being amplitude insensitive, the TOFD MAN System is not critically dependent on good acoustic coupling.

Fast and Easy Setup

The TOFD MAN features element libraries: Geometry Library, Material Library, Scanner Library, Probe Library, etc., which turn the setup process into a sequence of choices.

Mouse- and Finger-Friendly Interface

Design for Demanding Environments

The TOFD module case and the battery pack case are shockproof. In case the System falls down, the impact on its electronics is minimized due to the special design which protects the electronic module against mechanical shock.

The System has a wide operating temperature range: from –30 to +45°С.

The System is engineered to meet IP 65 specifications.

TOFD system software consists of a queue of tabs guiding the inspector through step-by-step setup procedure, data acquisition and analysis. Software is both mouse and finger friendly, so it can be used on various types of computers – tablets, laptops, desktops, monoblocks, etc. The setup process is greatly facilitated due to a wide usage of setup element libraries – Geometry library, Material library, Scanner library, Probe library, etc. Thus, the setup procedure is reduced to selecting proper elements from the libraries. Complete setup packs suitable for particular testing tasks can be saved and then loaded at any time.

Main software functions are distributed among the following tabs:

«Object» tab:

- selecting the test object geometry and setting up its dimensions;

- selecting the test object material;

- selecting the type of a weld bevel and setting up all its dimensions.

«Scanner» tab:

- selecting the scanner;

- setting up the scanner type: manual, motor-operated;

- setting up the spatial position of TOFD transducers pairs relative to the origin of the coordinate system;

- using up to 4 TOFD transducer pairs;

- carrying out encoder calibration.

«TOFD setup» tab:

- selecting the type of TOFD probes, TOFD wedges, or setup of their parameters;

- setting up the PCS – the distance between the index points of TOFD transducers and their shift relative to the welded joint axis;

- calculation and graphic display of the following parameters using TOFD Calculator:

- Spatial resolution (R);

- Scanning-surface dead zone (D);

- Backwall dead zone (D);

- Locus curve;

- Beam Spread.

«TOFD Calibration» tab:

- setting up the main UT parameters;

- carrying out the real-time TOFD calibration;

- real-time checkup of reflectors detection in calibration block;

- saving the calibration results.

«Data acquisition» tab:

- A-Scan + TOFD-Scan display during the testing process;

- carrying out the testing and data acquisition;

- displaying the current scanner position and the scanning speed;

- data synchronization by lateral wave during the testing process;

- considering the scanning direction and capability to rescan the regions with the acoustic coupling loss;

- saving test results.

«Data analysis» tab:

- review and analysis of saved data in a form of А-Scans and TOFD-Scans;

- quick and detailed analysis of test results using two measuring gates (type: normal, hyperbolic, manual hyperbolic);

- for all indications, the following parameters can be measured:

- their position in the object (X and Y-coordinates);

- their length (ΔX);

- their depth and height (Z, ΔZ);

- their type: “volumetric”, ˝top-surface breaking˝, ˝bottom-surface breaking˝ or ˝inner˝;

- building the defect table and saving it.

«Reports» tab:

- Sorting and filtering test results in the database;

- TOFD scan scaling for printout;

- Report preview;

- Printing reports.

- Transmitter;

- Receiver;

- Wedges;

- Internal crack.

- lateral wave;

- back wall echo;

- diffracted signal from the top tip;

- diffracted signal from the bottom tip.

TOFD transducers specification:

| Catalog number | Frequency, MHz | Element dia. | Object thickness | ||

| in | mm | in | mm | ||

| TWS10-3-TOFD 3/8" | 10 | .125 | 3 | .390-.600 | 10-15 |

| TWS10-6-TOFD 3/8" | 10 | .250 | 6 | .600-1.4 | 15-35 |

| * TWS5-6-TOFD 3/8" | 5 | .250 | 6 | 1.4-2.0 | 15-50 |

| TWS5-12-TOFD M16 | 5 | .500 | 12 | 2.0-4.0 | 50-100 |

| TWS3-12-TOFD M16 | 3 | .500 | 12 | 4.0-8.0 | 100-200 |

| TWS2.5-12-TOFD M16 | 2.5 | .500 | 12 | 8.0-6.0 | 200-300 |

| TWS2.25-12-TOFD M16 | 2.25 | .500 | 12 | 8.0-6.0 | 200-300 |

| TWS3-8-TOFD M16 | 3.0 | .325 | 8 | 4.0-8.0 | 100-200 |

| TWS2.5-8-TOFD M16 | 2.5 | .325 | 8 | 4.0-8.0 | 100-200 |

| TWS2.25-8-TOFD M16 | 2.25 | .325 | 8 | 4.0-8.0 | 100-200 |

TOFD wedges specification:

| Catalog number | Refracted angleo |

| WS45 L-3/8"-TOFD | 45 |

| WS50 L-3/8"-TOFD | 50 |

| WS60 L-3/8"-TOFD | 60 |

| * WS70 L-3/8"-TOFD | 70 |

| WS45 L-M16-TOFD | 45 |

| WS50 L-M16-TOFD | 50 |

| WS60 L-M16-TOFD | 60 |

| WS70 L-M16-TOFD | 70 |

* included in the standard kit

| Testing objects parameters | |

| Thicknesses | .25 - 2 in (6 - 50 mm) |

| Diameter for cylindrical objects | from 12 in (300 mm) to flat |

| Diameter for spherical objects | from 33 ft (10 m) to flat |

| Profile types | any |

| Scanner (with all electronics onboard) | |

| Dimensions (L×W×H) | 380×310×240 mm |

| Weight | 7,5 kg |

| Number of TOFD pairs | 1 |

| Coupling liquid supply | individually for each probe |

| Compatible probes and wedges | |

| Frequencies | 1-15 MHz |

| Angles (L-wave) | 45°, 60°, 70° |

| Measurement | |

| Number of cursors | 2 |

| Types of cursors | Conventional (cross) Hyperbolic |

| Manual positioning | ✔ |

| Automatic positioning | ✔ |

| Absolute measurements | ✔ |

| Relative measurements | ✔ |

| Indications table | ✔ |

| Indications parameters | X, X1, X2, dX Z, Z1, Z2, dZ Type (Point, Top, Bottom, Middle) Amplitude |

| Units | mm / in / us |

| Output fields | 5 |

| Unit connectors | |

| Pulser and Receiver | 2 × BNC |

| Encoder | ✔ |

| Power | ✔ |

| RS485 | ✔ |

| LAN | ✔ |

| Sync input | ✔ |

| Trigger output | ✔ |

| Pulser | |

| Types | Spike + SWP |

| Voltage (SWP) | 50 V, 100 V, 150 V, 200 V, 250 V, 300 V, 400 V |

| Energy (SWP) | 20 ns to 1000 ns with 10 ns step Manual & Auto modes |

| Voltage (Spike) | Low: 50 V, High: 300 V |

| Damping | ✔ |

| PRF | from 15 to 6000 Hz |

| Receiver | |

| Range | Up to 100 us |

| Delay | Up to 100 us |

| Gain | 0 to 110 dB, with 0.1 dB step |

| Max signal input | 20 V p-p |

| Bandwidth | 0.2 MHz - 27 MHz |

| Filters | 1 MHz, 2-3 MHz, 4-5 MHz, 10 MHz, 15 MHz, Full band |

| Rectification | Full Wave |

| Signal Average | 2x / 4x / 8x / 16x / 32x |

Basic Supply kit:

- TOFD 2.2 Lite scanner (with electronics, battery and transducers on board);

- Software for MS Windows notebook/tablet;

- Charger;

- Manual guide (hard copy);

- Hard case.

- Portable water tank (3,52gal/16l) with motorized pump (2-4,5Bar);

Available at option:

- Rugged Notebook or Tablet PC with pre-installed TOFD Software;

- Additional transducers (see tab "Transducers");

- Extra battery.